Boat motor elevator. Hydraulic trim for outboard boat motor

Description

An electro-hydraulic boat engine lift (trim) is a device that maintains the optimal trim of the boat in motion for various operating conditions.

The principle of the trim operation is as follows: when the boat is moving on the water, you have the opportunity to achieve the most optimal angle of attack of the bow of the boat by adjusting the angle of inclination of the outboard motor with the trim, as a result of which the boat’s output to the glider will be improved, its speed qualities and fuel economy will improve.

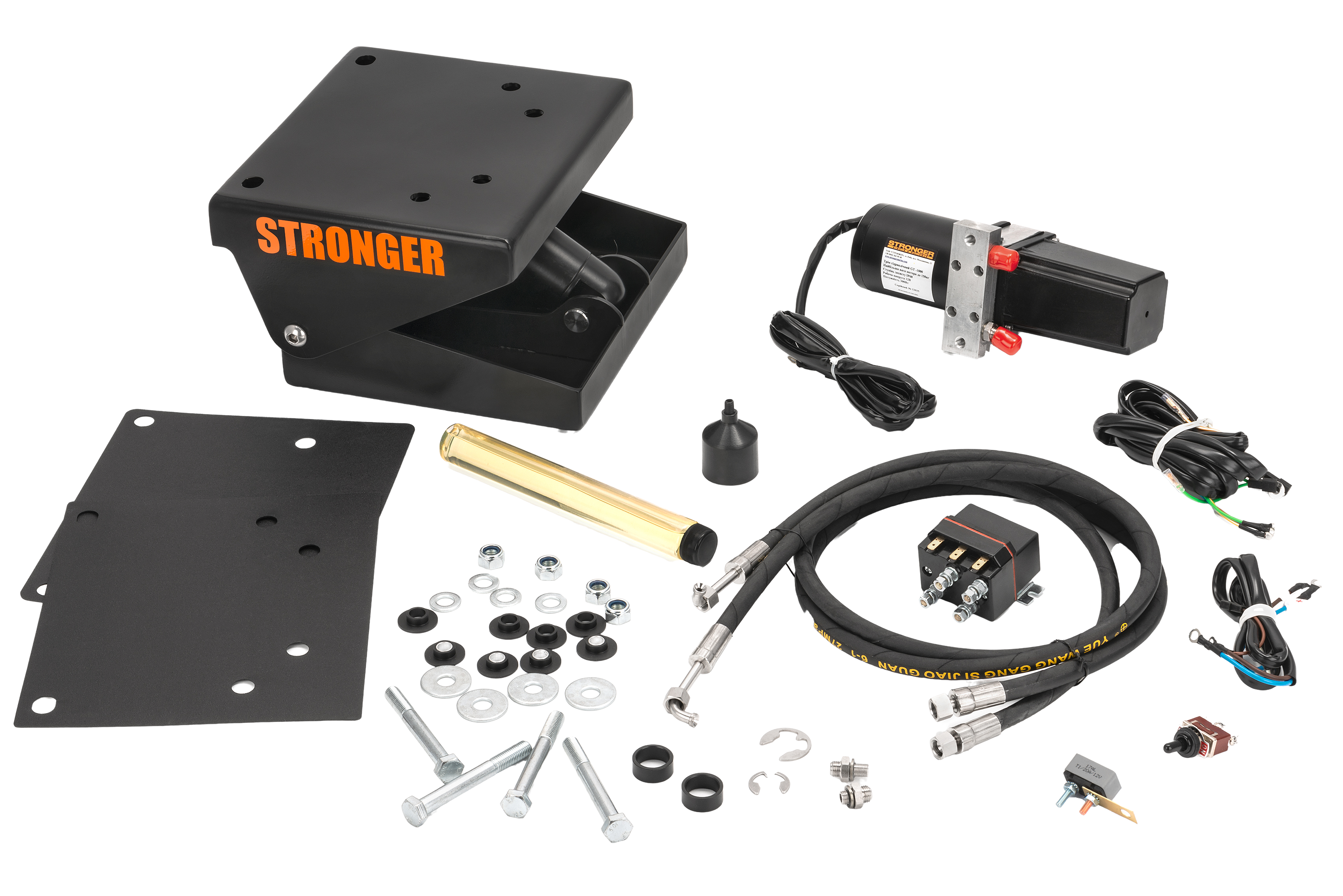

Technical description and configuration

Installing the device

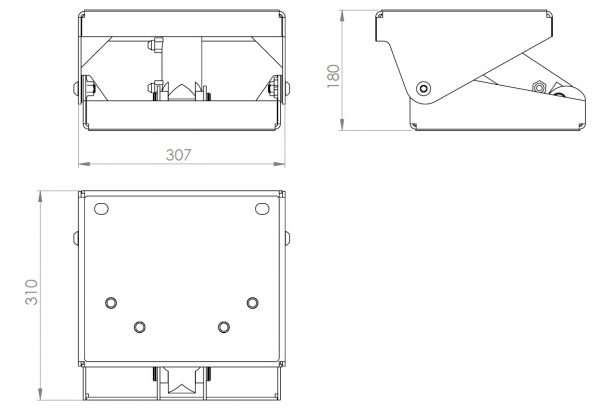

The product has all standard mounting holes drilled to fit most outboard motors up to 50 horsepower that were not originally trimmed by the manufacturer. If the holes for your motor mount, or the holes already drilled on the boat do not line up with those already on the trim, you may need to drill additional mounting holes yourself. Due to the fact that all manufacturers have their own characteristics for outboard motor mounts, we are not able to provide all options for mountings and their placement. For drilling holes, we recommend using stainless steel drills made from alloys containing cobalt. Perhaps in some cases, to mount the motor, you will need to remove the screw clamps (thumbs) from the mount of your motor. You may need to remove only the stubborn nickle in these clamps. In any case, we recommend mounting the motor on the trim using bolted connections using the standard mounting holes in your motor. Below is a figure showing the distances between the main mounting holes. Before attaching the trim to the stern of the boat, make sure your motor holes line up with those already on the trim, or drill new ones with a diameter of 16 mm.

Device dimensions

Holes for attaching to the boat transom

Outboard motor mounting holes

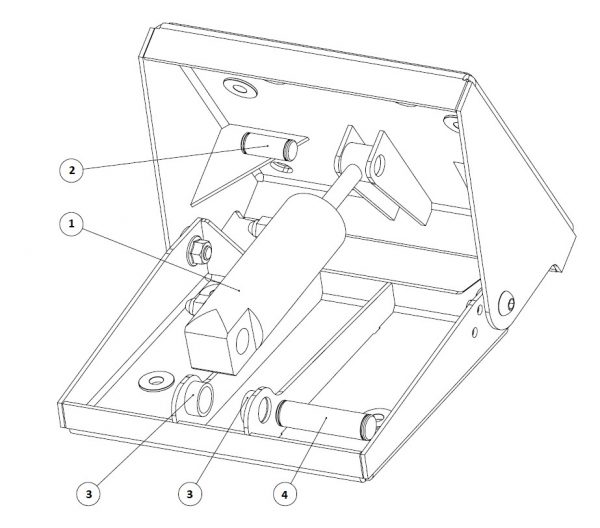

Refer to the installation manual for your outboard motor to drill the correct size mounting holes. Mounting hardware is supplied with the product for attaching the hydraulic trim to the boat transom. Make sure you have separate hardware to further attach the motor to the trim. These fasteners are not supplied with the device. Next, you will need to attach the trim to the boat transom. To do this, you need to disconnect your outboard motor from the transom if it was already installed. Then, on the already drilled holes of the motor mounting, install the trim using the fasteners and fix everything tightly. Refer to the figure below for how the insulating elements should be installed to prevent galvanic corrosion.

Side to boat transom

Outboard motor side

(The holes that are already drilled in the trim fit most outboard motors up to 50 horsepower without trim that are on the market. If you are performing the initial installation, then in this case it is advisable for you to contact the specialists and entrust them with the installation of the device. If you are still going to carry out the installation yourself, then in this case you need to install the trim exactly in the middle of the stern of the boat, having previously measured the necessary distances on both sides. Then align the top edge of the trim mounting pad with the top of the stern of the boat and then mark with a marker where you can drill further holes.

After you have drilled the holes and attached the trim to the boat transom, you need to reinstall the hydraulic cylinder as shown in the figure below. 1. Hydraulic cylinder 2. The upper rod of the hydraulic cylinder 3. Centering liners of the lower rod of the hydraulic cylinder 4. The lower rod of fastening of the hydraulic cylinder

Next, you proceed to connect the hydraulic station, replace the plugs with fittings on the cylinder and connect the station to the cylinder with hydraulic hoses. You can familiarize yourself with this process in the instructions for the trim.

Connecting the device to the battery

In order to connect the electrical part of the hydraulic lift, please use the connection diagram shown in the figure below.

Exploitation

For a quick start from the water and for the boat to glide, you need to lower the trim to the lowest position. This will pull the foot of your motor as close to the stern of the boat as possible. Then, after the boat has entered the glider, you make further adjustments to the tilt (angle of attack) of the engine. Pressing the up key, the trim begins its ascent, the motor leg begins to move away from the boat transom. You need to achieve a position where the anti-cavitation plate is strictly parallel to the bottom of your boat. In this case, you will have the most optimal speed limit, as well as a fuel economy mode. Trim control is carried out using a non-latching three-position toggle switch or control panel. The toggle switch control allows you to raise and lower the trim to the extreme positions, as well as to make manual adjustments by short pressing up or down. This option is basic, and the motor position will be adjusted anew each time. If you want more precise control with the ability to memorize a favorite position in this case, you will need to additionally purchase a panel and a trim control unit.

Using the control panel, you will be able to raise and lower the trim to the extreme high and low positions. You will be able to fine-tune step-by-step adjustments by briefly pressing the up or down keys in 2 cm trim steps to either side. Also, you will be able to memorize your favorite position in which your boat will have the highest efficiency. To do this, you need to enter the data into the nonvolatile memory by pressing the M key on the device control panel. And in the future, after the boat leaves the glider, you will only need to press one key M and the trim itself will be in the position you predefined.